Custom Hardware Development & PCB Design Services

From concept to production: creating reliable, optimized electronic hardware solutions

Turning Innovative Ideas into Functional Hardware

At NeoMikro, hardware development is the foundation of our expertise. Our experienced engineering team specializes in creating custom electronic hardware solutions tailored to your specific requirements and industry standards.

We handle every aspect of the hardware development lifecycle, from initial concept and circuit design through PCB layout, prototyping, testing, and production support. Whether you need a single prototype or a production-ready design, our hardware engineers deliver solutions that balance performance, reliability, cost-effectiveness, and manufacturability.

With extensive experience across multiple industries and applications, we create hardware designs that stand up to the most demanding operational requirements.

WE SHAPE THE FUTURE

Our Systematic Hardware Development Approach

Requirements Analysis & Specification

We begin every hardware project by thoroughly understanding your needs, constraints, and objectives. Our engineers work closely with your team to define:

- Functional requirements and performance specifications

- Environmental and operational conditions

- Size, weight, and power constraints

- Cost targets and production volume expectations

- Regulatory and compliance requirements

- Interface and integration needs

This comprehensive analysis results in a detailed specification document that guides the entire development process and serves as our mutual reference point throughout the project.

Concept Development & Architecture

Based on the requirements specification, our engineers develop the system architecture that defines:

- Block diagram of all major system components

- Power distribution strategy

- Signal flow architecture

- Interface definitions

- Component selection criteria

- Preliminary bill of materials (BOM)

- Risk assessment and mitigation strategy

Multiple architecture options may be evaluated to identify the optimal approach for your specific needs, balancing performance, cost, development time, and reliability.

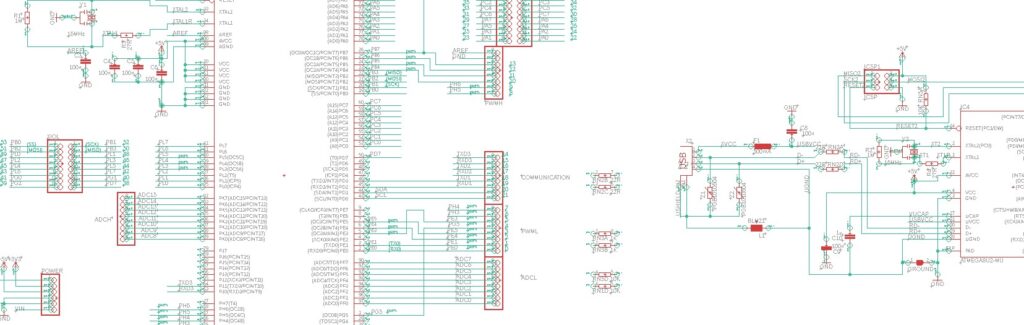

Circuit Design & Schematic Capture

Our electrical engineers develop detailed circuit designs for each functional block of your system:

- Microcontroller and processor circuits

- Power regulation and distribution

- Analog signal conditioning

- Digital interfaces and communication

- Sensor integration circuits

- Protection and filtering systems

Using industry-standard EDA tools, we create comprehensive schematics with full documentation, component selections, and design notes. Each circuit undergoes simulation and analysis to verify functionality before proceeding to PCB layout.

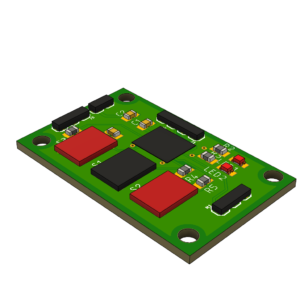

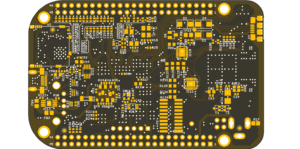

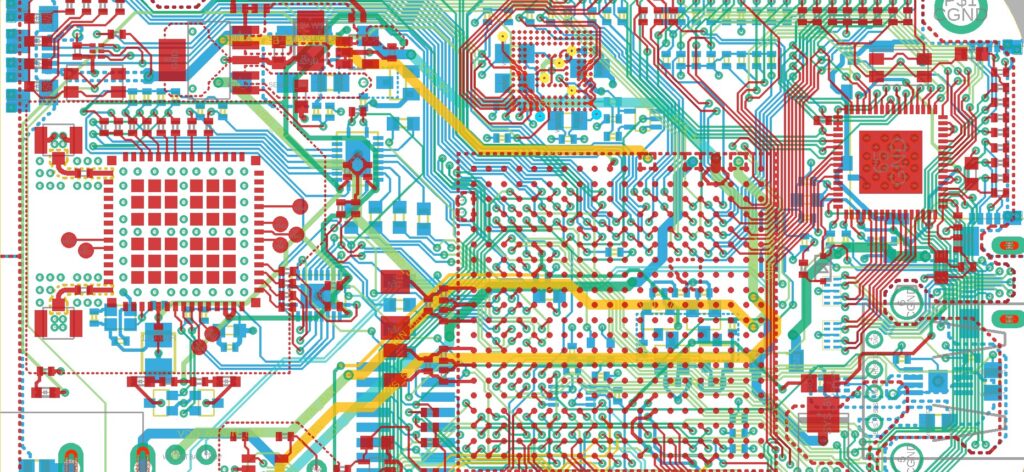

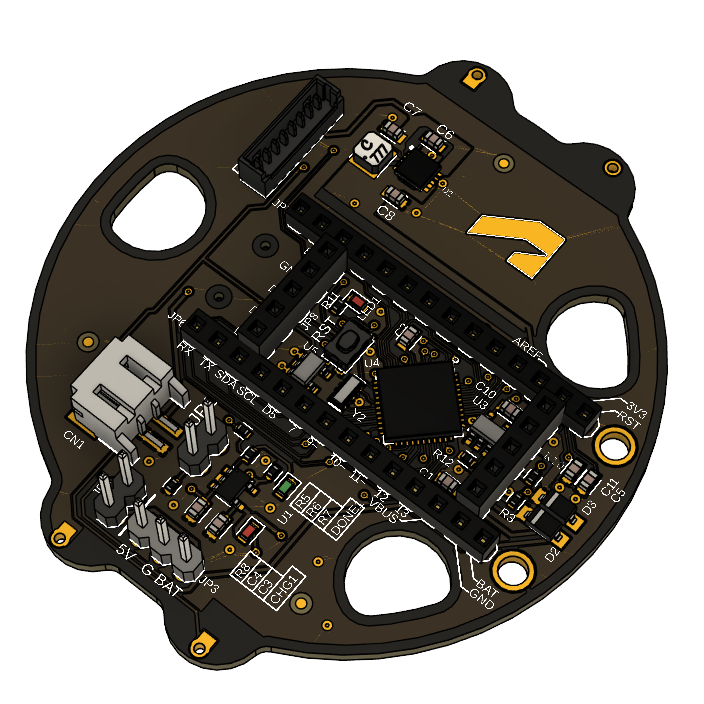

PCB Layout & Design

Our PCB design specialists transform schematics into optimized board layouts that adhere to industry best practices:

- Multi-layer designs optimized for signal integrity

- Controlled impedance routing for high-speed signals

- Proper ground plane design and power distribution

- Thermal management considerations

- EMI/EMC design techniques for compliance

- Design for manufacturing (DFM) optimizations

- Design for testing (DFT) features

- 3D modeling for mechanical integration

Each PCB design undergoes comprehensive design rule checking (DRC) and electrical rule checking (ERC) to ensure manufacturability and proper functionality.

Prototype Manufacturing & Assembly

We manage the production and assembly of prototype hardware to validate the design:

- Coordination with trusted PCB fabrication partners

- Component sourcing and bill of materials (BOM) management

- Assembly process definition and quality control

- First article inspection and verification

- Initial power-up and functional testing

- Revision tracking and change management

Our rapid prototyping approach allows for quick design iterations and verification of hardware functionality.

Comprehensive Testing & Validation

Each hardware design undergoes rigorous testing to ensure compliance with specifications:

- Automated functional testing of all features

- Environmental testing (temperature, humidity, vibration)

- Power consumption analysis and optimization

- Signal integrity verification

- EMC pre-compliance testing

- Reliability and stress testing

- Safety testing for applicable standards

- Longevity and endurance testing

Test results are documented in detailed reports, with any issues addressed through design refinements and retesting.

Final Documentation

Once testing confirms the design meets all requirements, we prepare comprehensive documentation for production:

- Final schematic and PCB files

- Complete bill of materials with approved vendors

- Assembly drawings and instructions

- Test specifications and procedures

- Compliance documentation

- User and maintenance documentation

Production Support

We can support you at production phase

- Manufacturing support and troubleshooting

We can also assist with production vendor selection, initial production runs, and ongoing manufacturing support..

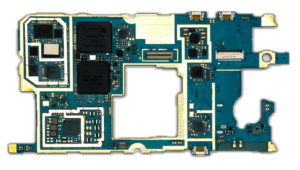

Embedded Systems Expertise That Drives Innovation

At NeoMikro, we leverage deep expertise across multiple microcontroller families to select the optimal platform for your specific requirements. Our engineers have extensive hands-on experience with industry-leading MCUs, allowing us to design solutions that balance performance, power consumption, and cost-efficiency.

STM32 Family

Our team has comprehensive knowledge of STMicroelectronics‘ STM32 ARM Cortex-M based microcontrollers. We excel in utilizing these versatile MCUs for applications requiring high performance, advanced peripherals, and excellent power efficiency. From the ultra-low-power STM32L series to the high-performance STM32H7 line, we select and implement the perfect STM32 variant for your project needs.

ESP32 Platform

Our team has comprehensive knowledge of STMicroelectronics‘ STM32 ARM Cortex-M based microcontrollers. We excel in utilizing these versatile MCUs for applications requiring high performance, advanced peripherals, and excellent power efficiency. From the ultra-low-power STM32L series to the high-performance STM32H7 line, we select and implement the perfect STM32 variant for your project needs.

nRF Series

For ultra-low power wireless applications, we specialize in Nordic Semiconductor’s nRF series. Our team implements Bluetooth Low Energy (BLE), Thread, and other protocols using nRF51, nRF52, and nRF53 series devices. These solutions are ideal for battery-powered devices requiring long operational life and reliable wireless connectivity, such as wearables, remote sensors, and asset tracking devices.

PIC & Atmel Microcontrollers

Our experience with Microchip’s PIC microcontrollers spans multiple generations and variants. We leverage these reliable MCUs for applications where stability, peripheral flexibility, and established ecosystem support are essential. Our engineers are adept at maximizing the capabilities of PIC16, PIC18, PIC24, and PIC32 series for industrial control, motor management, and sensor applications.

ARM Cortex-M Core Expertise

Beyond specific manufacturer families, our team has deep understanding of ARM Cortex-M architecture fundamentals. This cross-platform expertise allows us to efficiently work with various ARM-based MCUs from manufacturers including NXP, TI, Infineon, and others. We can select the most appropriate platform based on your specific requirements rather than being limited to a single ecosystem.

Other Hardware Capabilities

Power Electronics

We specialize in power supply and management systems:

- Switch-mode power supplies (buck, boost, buck-boost)

- Linear regulation for sensitive circuits

- Battery charging and management systems

- Solar and energy harvesting circuits

- Power sequencing and monitoring

- Overcurrent and overvoltage protection

- Motor drivers and control circuits

- LED drivers and lighting control

Our power designs emphasize efficiency, reliability, thermal management, and compliance with relevant standards.

Analog Circuit Design

We create high-performance analog circuits for a wide range of applications:

- Signal conditioning and amplification

- Precision instrumentation amplifiers

- Sensor interface circuits

- Data acquisition systems

- Filters and signal processing

- Reference voltage and current sources

- Temperature compensation circuits

- Low-noise designs for sensitive measurements

Our analog designs are optimized for accuracy, stability, and noise immunity even in challenging environments.

Communication & Interface Design

We implement a wide variety of communication interfaces:

- Wireless interfaces (BLE, WiFi, LoRa, Zigbee)

- Industrial protocols (Modbus, CAN, RS-485)

- Standard interfaces (USB, UART, SPI, I2C)

- Ethernet and network connectivity

- Custom proprietary interfaces

- Level shifting and isolation circuits

- Antenna design and RF circuits

- High-speed digital interfaces

Our interface designs ensure reliable communication while maintaining signal integrity and minimizing interference.

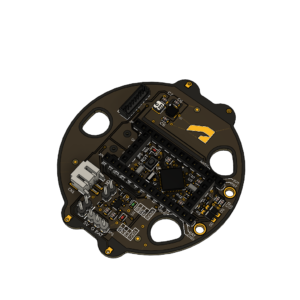

Sensor Integration

We excel at integrating various sensors into hardware designs:

- Environmental sensors (temperature, humidity, pressure)

- Motion and position sensors (accelerometers, gyroscopes)

- Proximity and distance sensors

- Flow and level sensors

- Optical and image sensors

- Current and voltage sensing

- Gas and chemical sensors

- Biometric and medical sensors

Each sensor integration includes proper signal conditioning, calibration circuits, and data processing considerations.

Frequently Asked Questions About Hardware Development

What is the typical timeline for hardware development?

Hardware development timelines vary based on complexity. Simple designs may take 2-3 months from concept to production-ready design, while complex systems can require 6-12 months. During our initial consultation, we’ll provide a detailed timeline based on your specific requirements.

How do you handle intellectual property for custom hardware designs?

We respect your intellectual property rights. All custom hardware designs we create for clients belong to them. We provide complete design files, documentation, and source materials, and can sign NDAs before project discussions begin to protect your ideas.

Can you modify or enhance existing hardware designs?

Yes, we specialize in both new hardware development and enhancement of existing designs. We can reverse-engineer existing hardware, add new features, improve performance, reduce costs, or solve reliability issues in current products.

Do you handle small production runs of your hardware designs?

While our primary focus is on design and development, we partner with trusted manufacturing facilities to support small to medium production runs. We can help coordinate PCB fabrication, component procurement, assembly, testing, and quality control.

How do you ensure hardware designs meet regulatory requirements?

We integrate regulatory considerations into the design process from the beginning. Our designs follow industry best practices for EMC/EMI, safety, and environmental compliance. We can design for specific standards (CE, UL, FCC, etc.) and support pre-compliance testing.

What documentation do you provide with completed hardware designs?

Our comprehensive documentation includes complete schematic diagrams, PCB design files, bill of materials (BOM), assembly drawings, test procedures, design notes, and user documentation. We can customize documentation based on your specific requirements.